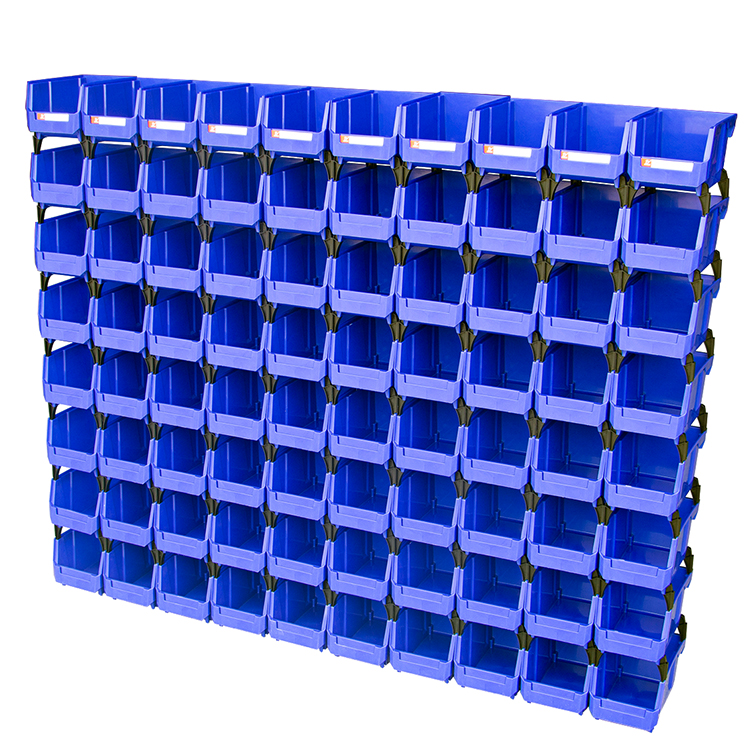

Efficient warehouse management is essential for businesses looking to streamline operations and reduce costs. In this blog post, we’ll explore how stackable storage solutions can significantly improve warehouse organization and logistics.

Space Efficiency: Warehouses often deal with limited floor space, and stackable storage helps maximize every square inch. By vertically stacking items, you can increase storage capacity without expanding the physical footprint of your warehouse.

Easy Inventory Management: Stackable storage bins and pallets can be labeled and organized systematically, simplifying inventory management. Barcode systems and tracking become more efficient when items are stored in easily accessible, stacked units.

Quick Retrieval: In a busy warehouse, time is money. Stackable storage ensures that items are within reach, reducing the time it takes to retrieve products for order fulfillment or shipping. This enhanced accessibility can lead to faster order turnaround times.

Reduced Damage: Stackable storage minimizes the need for manual handling and excessive movement of products. This can result in fewer incidents of damage to goods during storage and retrieval, ultimately saving on replacement costs.

Flexibility for Seasonal Inventory: Businesses that deal with seasonal inventory fluctuations can benefit from stackable storage’s flexibility. You can adjust the number of stacks and the layout of your storage system to accommodate changing inventory needs.

Cost Savings: By optimizing space and improving organization, stackable storage can lead to significant cost savings in the long run. Reduced storage requirements and more efficient inventory management contribute to improved overall warehouse efficiency.

For warehouses looking to enhance their operations, stackable storage is a practical and cost-effective solution. It promotes organization, accessibility, and space optimization, all of which are crucial for maintaining a competitive edge in today’s fast-paced business landscape.